Add material for laminating top and bottom

Start

Pro

Description

The laminating function allows an additional layer to be added to each panel. This applies to both the bottom and top of the base material. These additional materials also appear on the cutting list, in the optimization report or in the Excel or CSV export files as desired.

Possibilities with Laminate

This laminate layers apply to both bottom and top of the base material. These additional materials also appear on the cutting list, in the optimization report or in the Excel or CSV export files as desired.

Specifically for these “thickening layers,” overlength can be specified, and the function can also be used for spray/paint layers, where the area of spraying can be filtered out of the model.

For users of Para-Flex Pro and higher, the thickness of a panel is automatically adjusted and the color on the top and bottom is also displayed corresponding the material properties in the database.

Lamination of whole boards

In case of using only fully laminated boards (rather than individual parts), it is more useful to create the laminated board in the material library and assign it to a panel. Having the material in the library makes it easier to apply the material combination more frequently.

If different finishes are used on the bottom and top and a matching appearance is desired, then use of the laminate function is preferable to the creation of a specific board material.

Basic steps of the laminating function

Adding a laminate material to the material list

First, make sure that the material you want to laminate with, has been added to your material list in the 3D model. So if necessary, create the material by clicking on the 3 dots in one of the material lists. The material selection lists for laminating are in sync with the material selection list on the Shop Floor tab.

For HPL a material thickness of 0.8 or 1mm (including glue) is often used. For paint layers a material thickness of 0mm is practical because the panels are first processed without a finish, the paint layer is usually applied after all the processing.

Adding laminate or finishing coat to a part

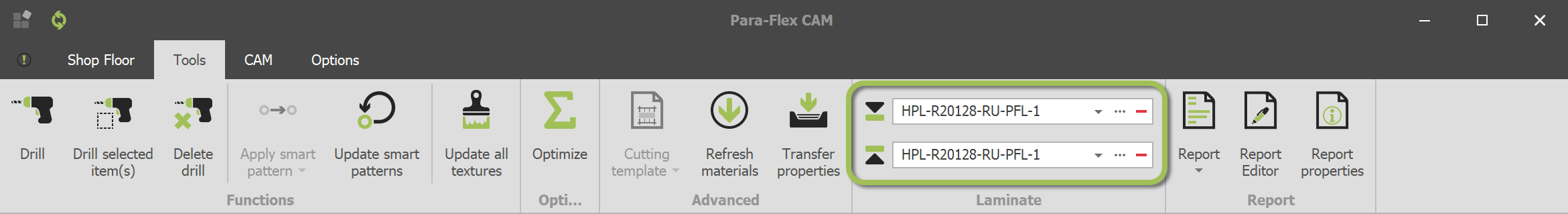

Select the part you want to add an additional layer(s) to and, if not already applied, attach a base material to it. To do this, select a material from the material list on the Workshop tab and turn on the Cutting or CNC process (or both, of course). On the Tools tab, the Laminate section shows two drop-down lists. The upper one determines the finish layer on the top of a panel, the lower list is for material application on the bottom.

Processing oversized laminate by default

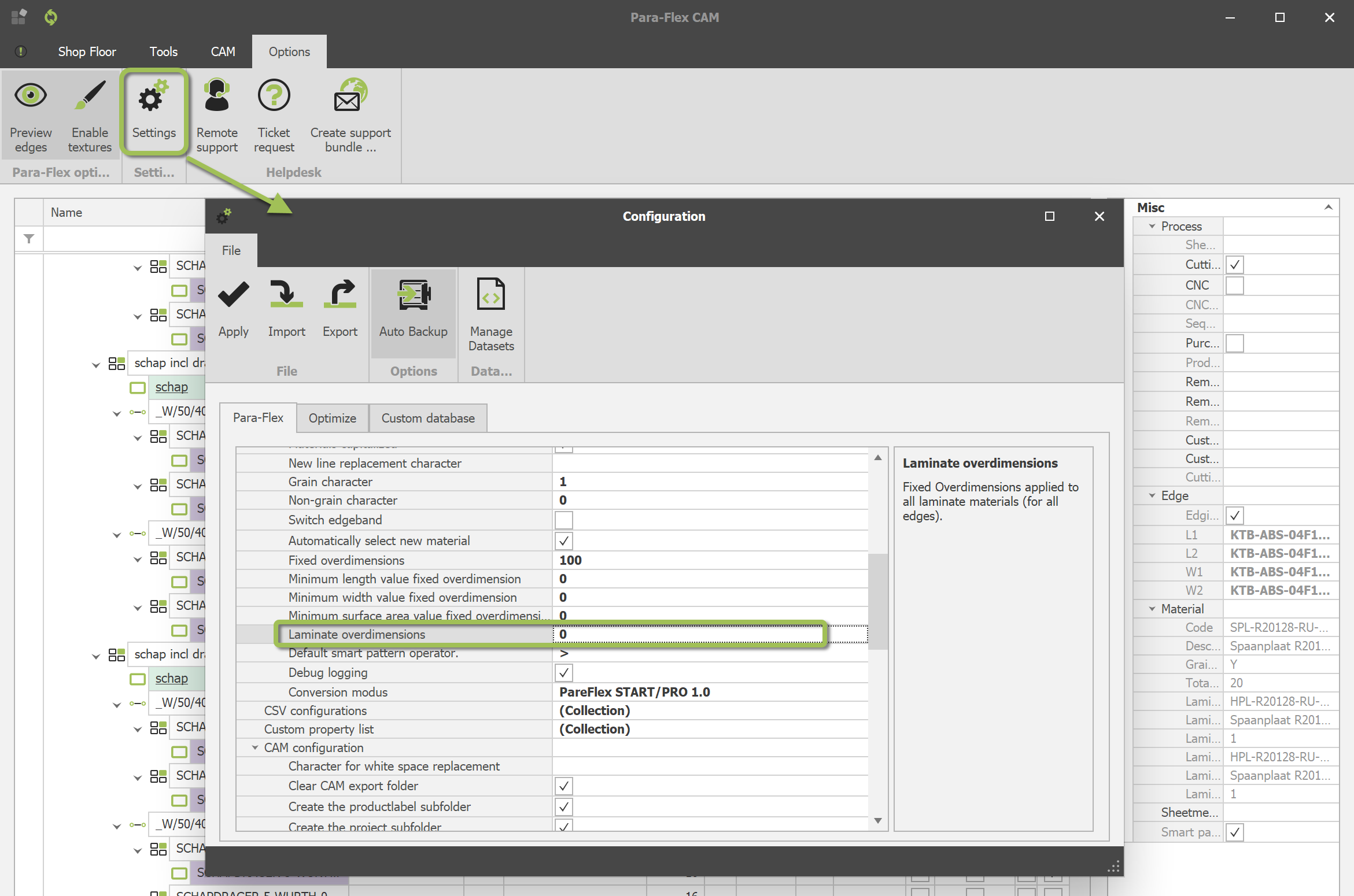

A fixed oversize for laminate parts can be set in the Settings menu.

This can be found through Options > Settings > Para-Flex tab. In the General Configuration list, search for “Output laminate with oversize (mm)”.

The oversize entered here is applied all around to the gross cut dimensions of a part.

Exporting laminates

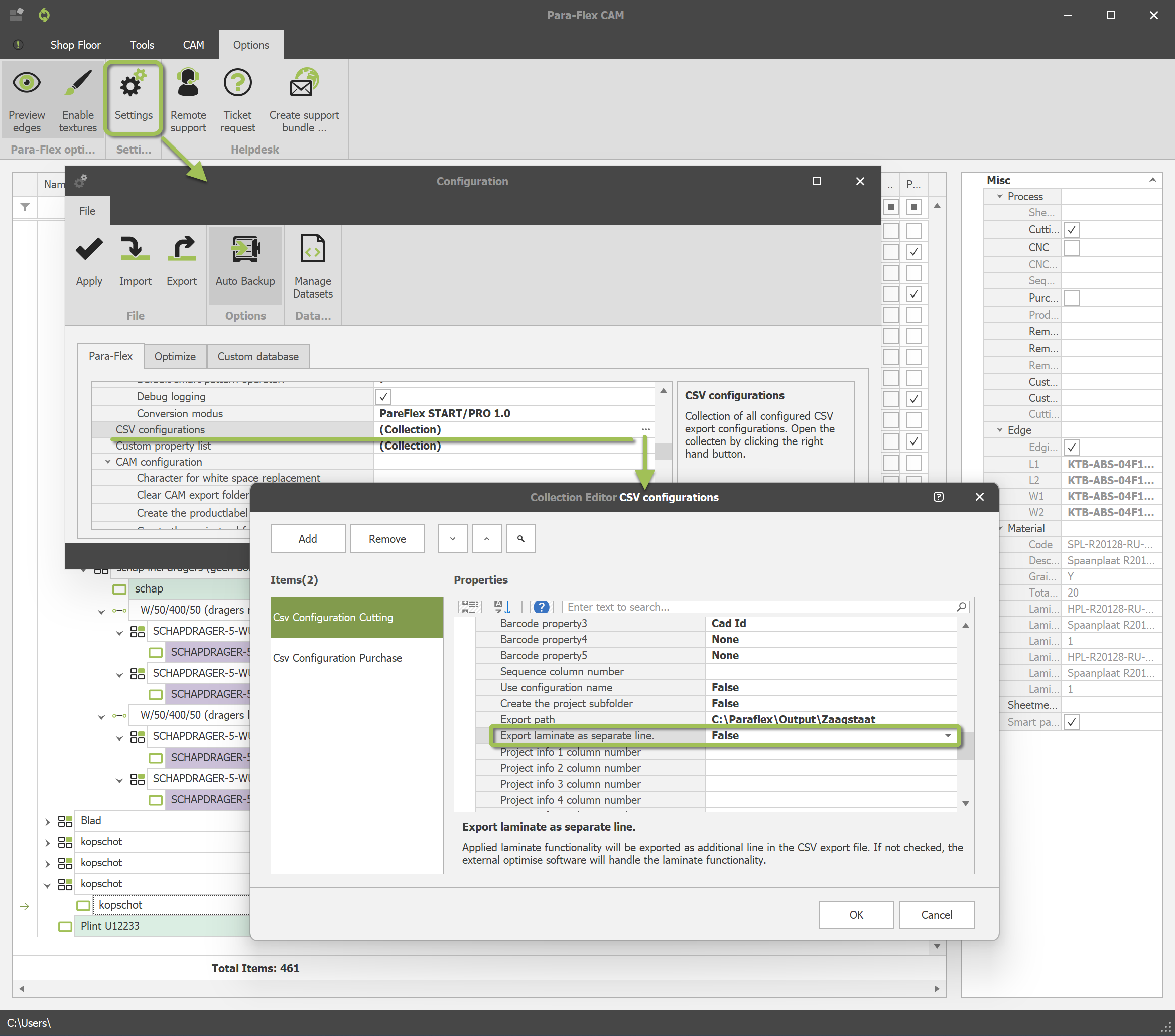

Depending on the workflow (lamination per part or entire board) you can choose to show the laminated parts separately from the base material in the output options. In the output files (CSV, Excel or a report) the part will then appear under the base material, and the finishing parts under the corresponding selected laminate materials (possibly with overlength).

This setting can be found through Options > Settings > Para-Flex tab. In the General Configuration list, search for “CSV Configurations” and click on the three dots on the right of it.

To enable the feature, check the set configuration (For example, Cutting) and set “Export laminate functionality as an additional rule” to True.

In short

Laminating is not used for simply laminating only, but also for thickening panels with a material of choice and applying layers of paint. By using this cleverly, a lot of extra information can be added to the model that can be of benefit to everyone in the work process.

Conditions

- The contents of these two material lists are identical to the material list of the basic material on the Shop Floor ribbon Bar.