Calculate drills within complete model

![]() Pro

Pro

Description

Applies drill operations within the complete scene to the respective parts. Information about how to use drills and their possibilities can be found below.

Keep in mind that drilling a selection of the scene is faster in complex models, so use Drill selected item(s) if preferred.

Conditions

- The drill functionality is only available for users of Para-Flex Pro and higher.

The Drill function explained

Para-Flex offers the possibility to automatically create holes in parts. Based on specific elements in the model, like furniture fittings or inserts, for example cut outs can be created in a wooden panel or a metal tube.

This function can save a lot of time and prevent mistakes, such as holes that are still in the old position while the part for which something needs to be cut out has already been moved.

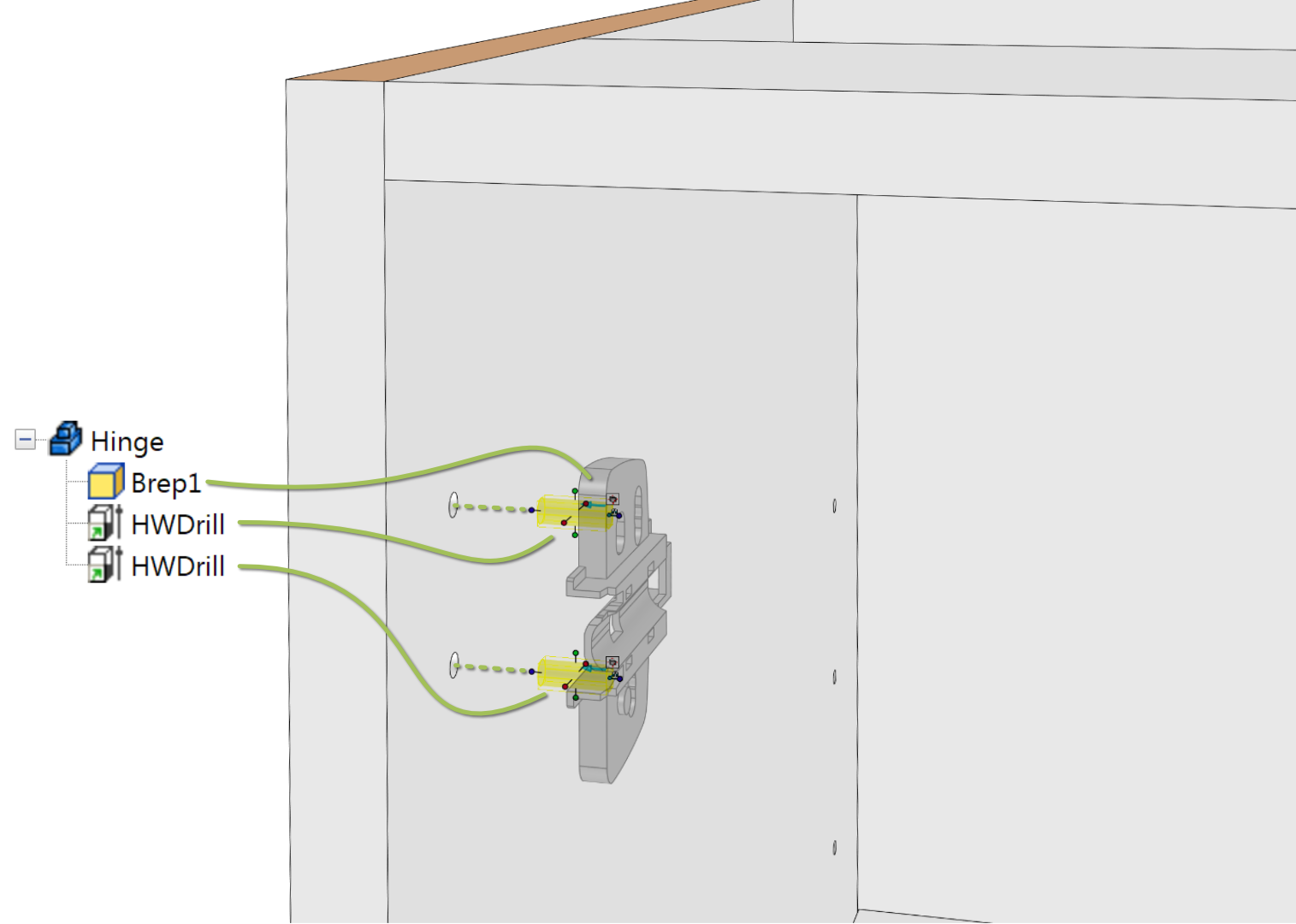

The impression to the right shows two drill-shapes drawn in the base of the hinge, resulting in two cut outs in the side panel of a cabinet.

Basics of using the Drill function

The operation of the Drill function is quite simple, in short: the drill command cuts every IntelliShape with ‘HWDrill’ in its name, out of other parts. Of course, with the exception of the part that contains this HWDrill-shape itself.

Drill shapes for creating a cut out should be drawn as an IntelliShape in the part it belongs to. Use positive IntelliShapes for this function, don’t use the Cut variants that remove material by themselves: use the shapes that ‘add material’ to the model. These shapes can be suppressed so they won’t be visible in the model, but still do their job. If the shape of a Drilling element has to be changed due to model updates (like Stretch Part/Assembly), keep it in Unsuppressed state.

For example, when a recessed LED profile is stretched, the shape that creates the cutout in the main element must also change size. This is only possible if the IntelliShape is not in Suppress status.

Based on these HWDrill shapes, the drill function creates the cut outs in all the parts with which they come into contact.

In the Para-Flex sample catalogs many parts contain drill shapes. They can be found when expanding a part (click on the plus sign in front of it). Look for a shape called HWDrill and if desired unsuppress it, they can be edited like every other IntelliShape in IronCAD.

Suppress or Unsuppress drilling shapes

The Drill feature sets any Drill IntelliShape to the unsuppress status before it is applied. After drilling, the state of suppression is returned to the original state as before using this function.

Tips

- The cutting shape should be an intellishape that adds material (though it creates cut outs), so use the positive basic shapes, not the Cut variants.

- If the model should look neat, set the drill shape to Suppress.

- If the IntelliShape needs to change in form due to possible model updates, set it to Unsupress.

Applying drills to parts

To provide parts with drilling shapes, works easy and intuitive. For example use the standard Shapes catalog to drag a shape on the relevant part. Keep in mind that these shapes are IntelliShapes, so they’ll become a component of the part they’re dropped on.

Also the anchor of the IntelliShape has to point in the direction the cutter head comes from.

In short, after reshaping the drilling shape, there are a few standard points to be checked:

- Rename the IntelliShape to ‘HWDrill’.

- Make sure the anchor is pointing in the right direction (towards the cutter head).

- If needed, suppress the IntelliShape to keep your design clean.

Recognizing holes

Although the name of a shape to be used for a drill operation has to contain ‘HWDrill’, every text can be added to this text to make identifying the result of this drill shape easier. For example a shape called ‘HWDrill – Hinge’ can be found as cut out shape in a side panel called ‘Hole_HWDrill – Hinge’. That makes it easier to recognize the origin of the cut outs.

Tip: Recognition of the name/text ‘HWDrill’ by the drill tool isn’t case sensitive.

Divide the model into assemblies

Not only for overviewing the project for your own, but also for speeding up the process of drilling, it’s recommended to divide the model into assemblies. When for example having dowels to be drilled in a panel it also works clearly and faster to combine the dowels and the panel into one assembly. An additional advantage of grouping these parts is that the dowels can easily be calculated using a pattern depending on the panel size.

The use of smart panels

To be able to use automatic CNC-programming and visual appearance of materials, it’s recommended to use parts modelled using so called ‘Smart Panels’. This parts act like normal blocks in IronCAD, but have been expanded with additional intelligence. This adds driving the thickness of a panel, recognizing the bottom and top side and applying banding and CNC reference to edges. Panels used in the catalogs provided by Dynfos are build up from smart panels.

Drawing cut outs and holes

As mentioned, it’s important drill shapes at one side of a panel all have the Achor pointing in the same direction, towards the cutter head comes from. When the Anchor is pointing in the other direction, it depends on the settings in the post processor how this is handled.

It is possible, among other things, that holes with a ‘wrong’ anchor direction are simply ignored. Also the processor could generate two programs, each for one side of the panel; or add a so called NC-Stop to give the ability to rotate the panel on the machine. It’s even possible the CNC machine starts drilling the hole from the wrong side, even when the shape doesn’t protrude through the base plane.

Extended control of drilling functions

To have more control over whether Drill Shapes are performed in all or specific sections, tags can be added. The following is a brief summary of the options, followed by a more detailed description of each feature.

- Elements with part names that starts or end with “_” are not drilled.

- HWDrill shapes that contains “+” in the name overules option 1.

- HWDrill shapes that contains “#1” in the name, drills only elements that are in the same assembly.

- HWDrill shapes that contains “#2” in the name, drills only element that are in different assembly.

Exclude parts from the drilling operation by using "_"

When a part has to be ignored by drill operations, simply start or end the name of that part with an undeerscore ‘_’. This is for example useful when having a window frame that consists of multiple parts, the frame has to createa hole into the wall, but should not cut out the glass. In this cas the part “Glass panel” could be renamed to “Glass panel_” or “_Glass panel”

Drill in all parts by using "+"

As mentioned above , if parts are not to be provided with cutouts, starting or ending the part name with a “_” (underscore) can be used.

Sometimes it is desired to have certain bores and not others in a part. For example, in the case of a rib milled partially into a shank: A separate part used as a drill shape creates space for the rib in the shank, but this drill shape should not provide the rib itself with a cutout (you could add “_” to the name of the rib). However, you do want a drill in this rib for a cable tray….

For this purpose, you can have a drill shape override the exception by adding a “+” to the name of the drilling shape, such as “+ HWDrill (Feedthrough Cap). This drill shape with a “+” ignores the exclusion of parts with a “_” within the same assembly. Thus, the cable grommet (with the +) is still spaced out in the rib despite the exclusion (_) of drilling influences.

Apply drill only whitin same assembly by using "#1"

When an HWDrill shape is used with in the name ‘#1’, it drills only into elements that are in the same assembly or parent assemblies. Parts in their own assembly (possibly within the same parent assembly) are not affected by this drill shape.

Apply drill only whitin other assemblies by using "#2"

When an HWDrill shape with a name containing “#2” is used, it only drills into elements that are in other assemblies. Parts within the same assembly are not affected by this drill shape, even parts that are not in an assembly at all are excluded from this cutout.

Drilling functions and selecting items

Items in IronCAD can of course have been selected before using the Drill functions. The buttons available are Drill and Drill selected item(s). While items are selected, both functions can be used, but there are some differences between these two approaches:

Button: Drill selected items

This speeds up the drilling process by suppressing unselected parts. Note that these suppressed parts no longer cause drillings! In a single assembly with no drilling influences from outside into this assembly, this is not a problem. But keep in mind that the drilling result might be incomplete if parts from outside should drill into the selected items.

Selecting items and using normal Drill

Doing this does not offer any speed gain, but the drilling result is limited to the selected parts.

In the background, the complete 3D model is checked for drill shapes present, but the cut-outs are only applied to the selected parts.