Information and guidelines for a smooth workflow

Start

Pro

For an even faster workflow with IronCAD and Para-Flex, some basic information is very helpful. Below is a list of guidelines that can help master the software and speed up the entire process from design to production. Click on a toggle below to open it and read more information.

One IronCAD session at a time

The add-in Para-Flex works on a single session of IronCAD at a time.

Certain functions (e.g. updating Sizebox information) stop working when opening multiple IronCAD sessions at once. The connection to Para-Flex breaks.

The Para-Flex Pro-license connects to the first opened session of IronCAD/Para-Flex. When starting a second session, Para-Flex Start will show, instead of Para-Flex Pro. The add-in stops running properly since it’s not clear to which session it should connect.

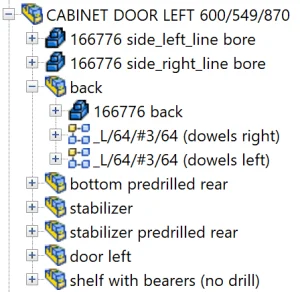

Dividing the model into assemblies

We advise to divide models into assemblies for a better overview and a faster drilling process. E.g. when dowels need to be drilled into a panel, put the respective dowels and panel together into one assembly. An additional advantage of grouping them is that the dowels can easily be calculated according to a pattern that relies on the panel size.

The use of smart panels (For Pro/CAM users)

For users of Para-Flex Pro and higher it’s recommended to use parts modeled using so called ‘Smart Panels’. This gives possibilities for automatic CNC-programming and visual appearance of materials.

Parts based on Smart panels behave like normal blocks in IronCAD, but are enhanced with additional intelligence. For example, the thickness and textures of Smart Panels can be controlled by Para-Flex, bottom and top edges are recognized, and sides for edge finishing are visually displayed in IronCAD. Compared to standard Parts/IntelliShapes, the Smart panels also offer capabilities for automatic CNC programming, such as CNC reference side and tooling.

Panels used in the catalogs provided by Dynfos are build up from smart panels.

Origin and labeling of edges

Every 3D-shape in IronCAD has a direction of extrusion. In case of a panel, think about the basic contour (often a rectangular shape) extruded in a straight direction to create the material with the correct thickness. IronCAD indicates the direction of extrusion by a blue arrow starting at one of the corners of the Cross Section (or Contour).

The exact position of the arrow doesn’t matter for the results of the CNC program, but its starting point indicates the origin (0, 0, 0) of the panel. Based on that origin the labeling of the edges (L1, L2, W1 and W2) is done. When the object is shown as in the images in this item (extrusion arrow is pointing downwards), the edge to the right of the arrow is labeled L1. The rest of the edges is labeled clockwise starting from L1: W1, L2, and W2.

Standard cabinets

Materials used from catalogs provided by Dynfos standard have L1 set as reference edge. Cabinets from one of these catalogs are modelled in the way that edge L1 is the front of the panel. By default this side has edgebanding applied and acts as CNC Reference.

Note

Para-Flex can operate up to 4 sides per panel. Controll over more sides will be added in the future. If this is already a desired option for you, please contact us.

Extrude direction arrow

As mentioned in the item Origin and labeling of edges above, the extrusion arrow determines the origin of parts. The direction of this pointer affects a number of things, for instance changing the thickness and the boards bottom or top side.

Material thickness

When changing the thickness of a panel by selecting a new material, the origin stays at the same position. Given this fact, the panel thickness will increase or decrease in a predictable way.

Top or bottom of panel

The direction of the extrusion arrow determines the top or bottom of a panel, which can relevant for CNC machining. When a panel is only being contoured, the arrow points towards the bottom of the panel, also the machine bed, as the top of the panel is pointing towards the cutter head.

When processing a panel with both sides containing drill shapes, by default, the side with the most drill shapes is treated as the top side and machined first.

Standard cabinets

When changing the material thickness of a standard cabinet, panels will increase towards the outside of the model, because in these models the extrusion arrow is directed outside. This way internal items, like shelf supports or drawers, will stay at the right position, connected to the side panels. The cabinet can be easily adjusted to the desired dimensions using the stretch tool.

Drawing contours

In order to get files as desired for processing on a CNC machine, a number of guidelines will have to be taken into account.

Using Chamfer/Blends instead of Cross section editing

Chamfers, cutouts and blends can be drawn using different methods. Though, every method can lead to different programs for CNC machining.

Editing the cross section of a panel gives a lot of freedom, but be aware resizing or stretching parts in one direction scales the cross section (when no constraints are used).

Also the recognition and visualization of the standard edges (L1, W1, L2, W2) and the CNC reference edge, can be disturbed when new lines are added to the cross section of a panel. To get around that, it is best to use Cut out shapes, Chamfer or Blend features, which also eliminates the problem of aspect ratio locks between the length and width of a shape.

See the tip below for using Contour Handles for faster editing shapes.

Contours in the Cross-sections of shapes

A contour completely shaped in the Cross Section of a panel will be exported to a CNC program exactly like drawn. Keep in mind that drawing both the outer contour as the inner contour (including drills) in one cross section can’t be handled by the CAM module. For example the outer contour should be drawn in the Cross Section of the panel, and the inner contour, cut out or drills should be drawn in the cross section of another IntelliShape like a Cut Extrude.

Drawing curved lines

Curved lines in the cross section of a shape must consist of arcs to be properly processed to the CNC program. Since the CAM module doesn’t recognize Spline, Bezier and Elipse curves, these lines must be drawn in (or converted to) arcs before they are exported to CNC.

Tip: Switch type of Edit handles

The handles of an IntelliShape normally are set to so called Sizebox handles. This method resizes the complete shape without taking into account the aspect ratio of the shape. Certain elements in the Cross Section are lockable by applying constraints, but often a faster method is switching to Contour handles. Using Contour Handles the Cross Section of a shape can be edited directly on the edges, without affecting other parts of the shape. When having an IntelliShape selected, hotkey TAB can be used to switch between the handle methods.

Long grain and short grain materials

Materials containing grain direction are (by default) only supported with the direction of the grain along the Length value of the board (so called ‘long grain’). For materials with a grain direction along the short side of the board (so called ‘short grain’), simply create a material and switch the length and width values. So entering the length value of the short side, in the Length field, and the length of the long side in the Width field.

Tip: Exclude parts from BOM and Para-Flex

Parts with Include this shape in BOM switched off in their properties in IronCAD, will not only be excluded from the Bill of Materials, but also ignored by Para-Flex. This is practical for cleaning up your working list and puts less strain on the system. Examples of items not to be handled by Para-Flex are environmental elements in the design like building structures or decoration.

After changing this setting for an item, refresh Para-Flex using the button in the upper left corner. This ensures that the underlying items (for example, in an Assembly) remain synchronized with IronCAD.